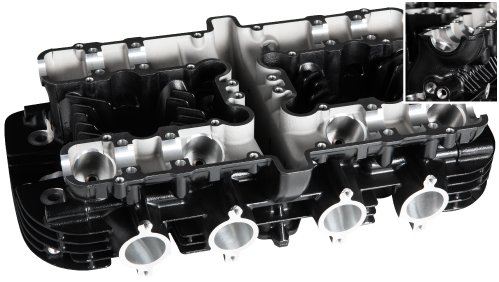

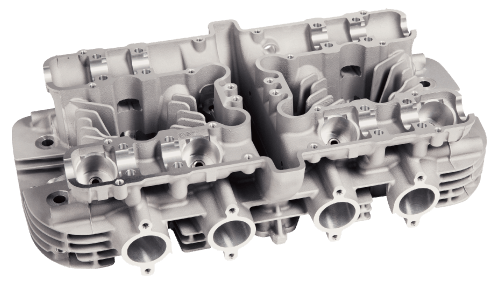

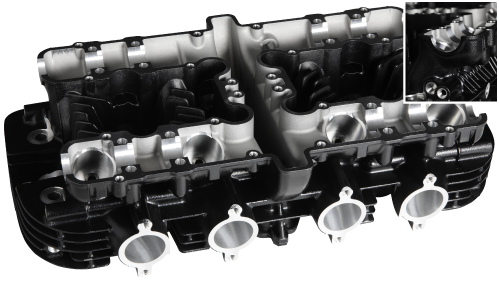

HF Z HEAD

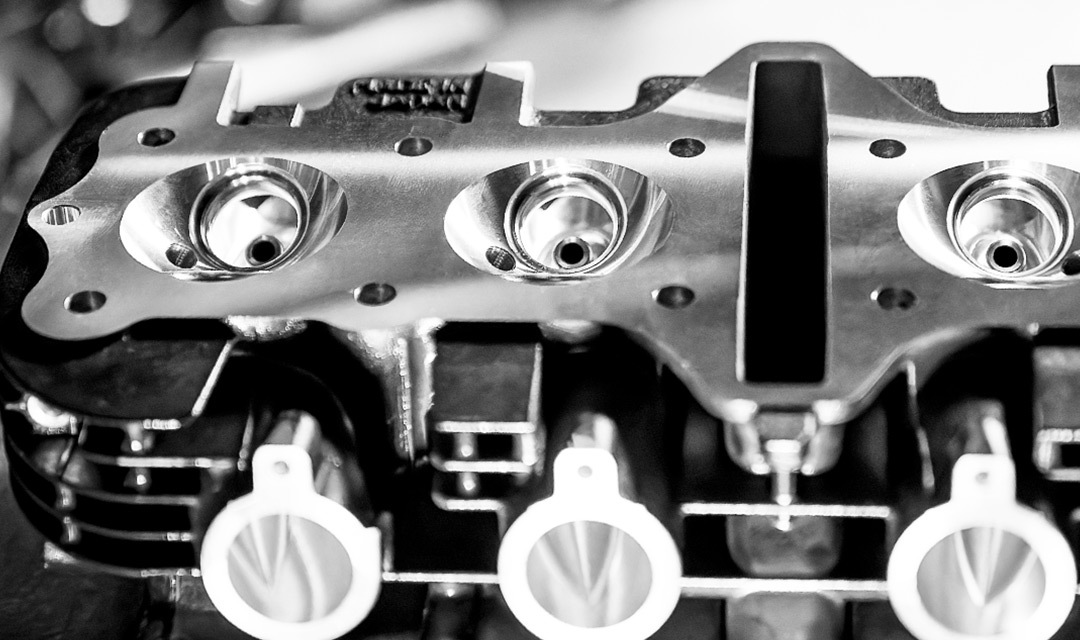

This tuned cylinder head for air-cooled Z has significantly improved all basic performance.

ALL MADE IN JAPAN from design to casting to final processing.

This tuned cylinder head for air-cooled Z has significantly improved all basic performance.

ALL MADE IN JAPAN from design to casting to final processing.

Available in two types:Round design and Square design.

The colors are black and silver.(Square type is only available in black.)

¥600,000 JPY plus tax

¥600,000 JPY plus tax

¥600,000 JPY plus tax

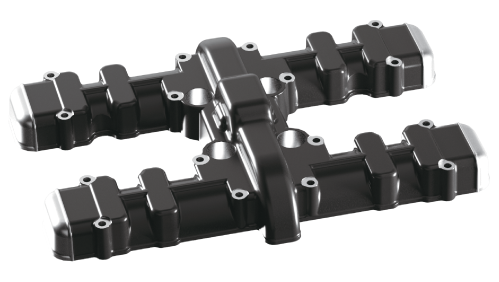

¥130,000 JPY plus tax

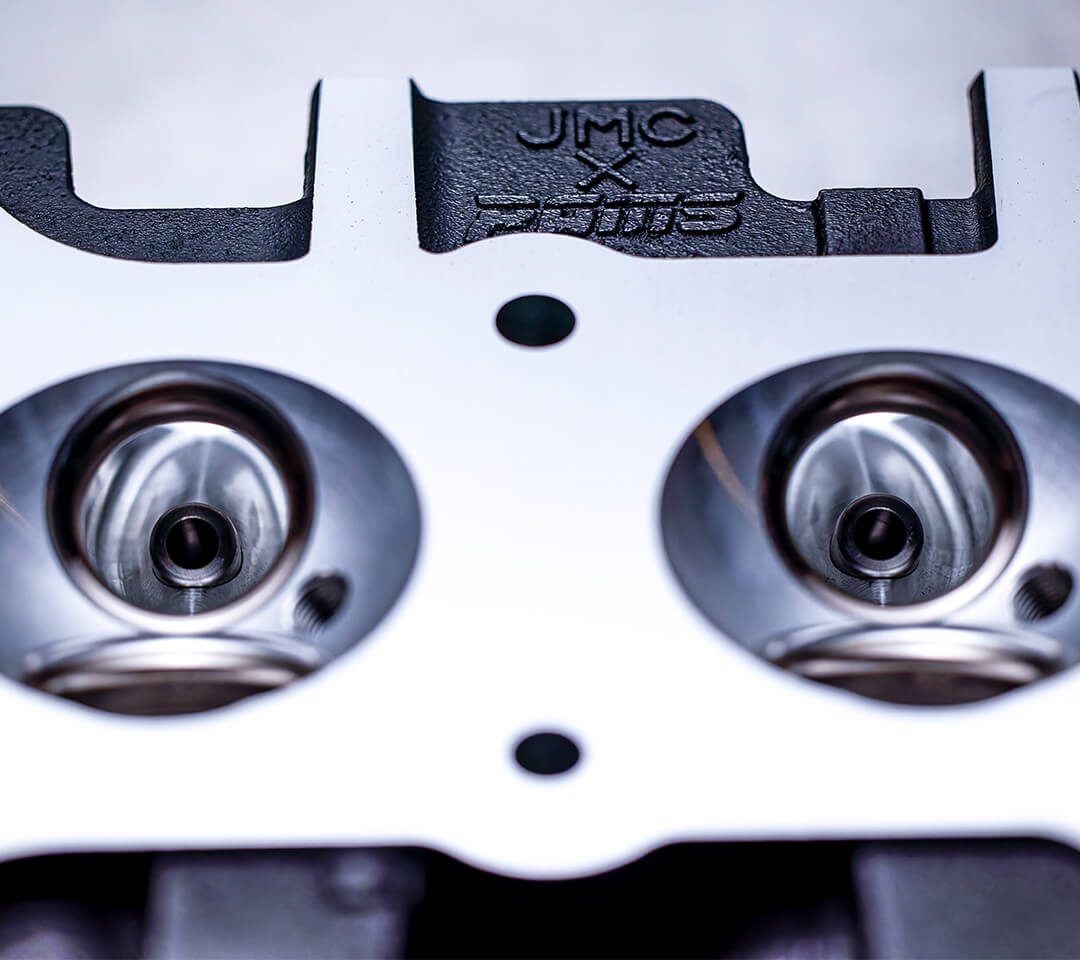

Headcover exclusively for HF Z HEAD (square design)

Cam nose clearance processed.

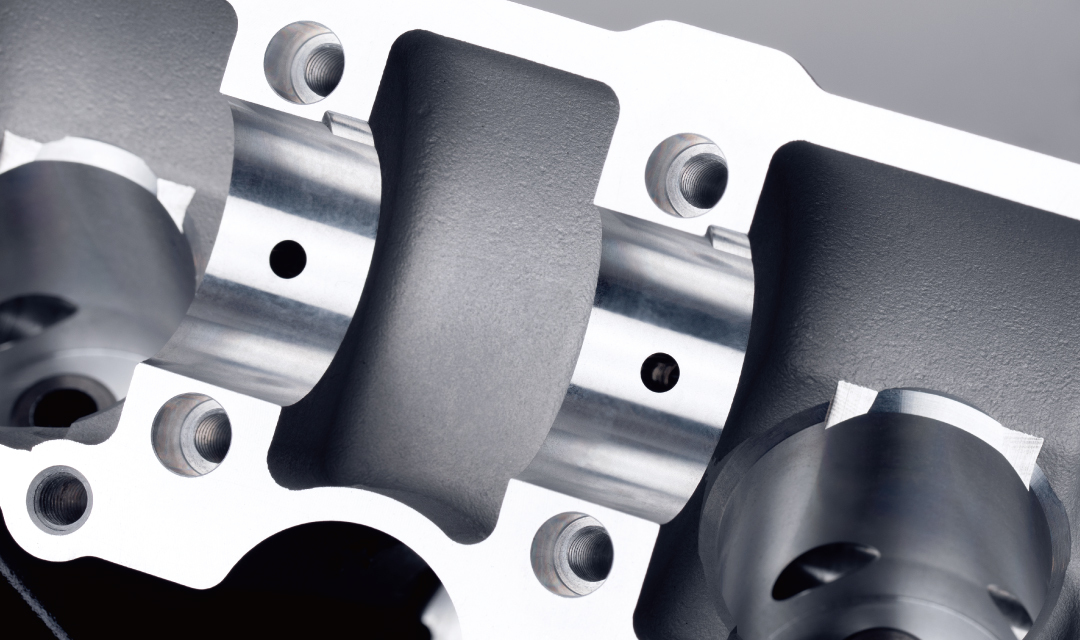

AC4CH+T6 is a casting material that improves cylinder heads' mechanical strength, heat dissipation, and thermal conductivity. It also provides high tensile strength, yield strength, fatigue strength, and corrosion resistance.

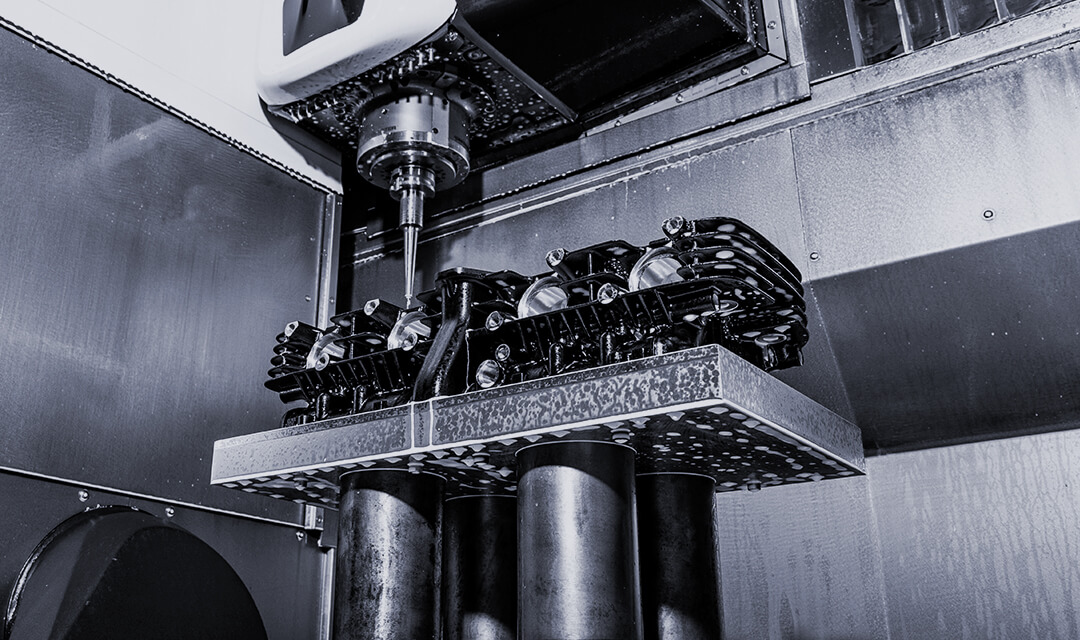

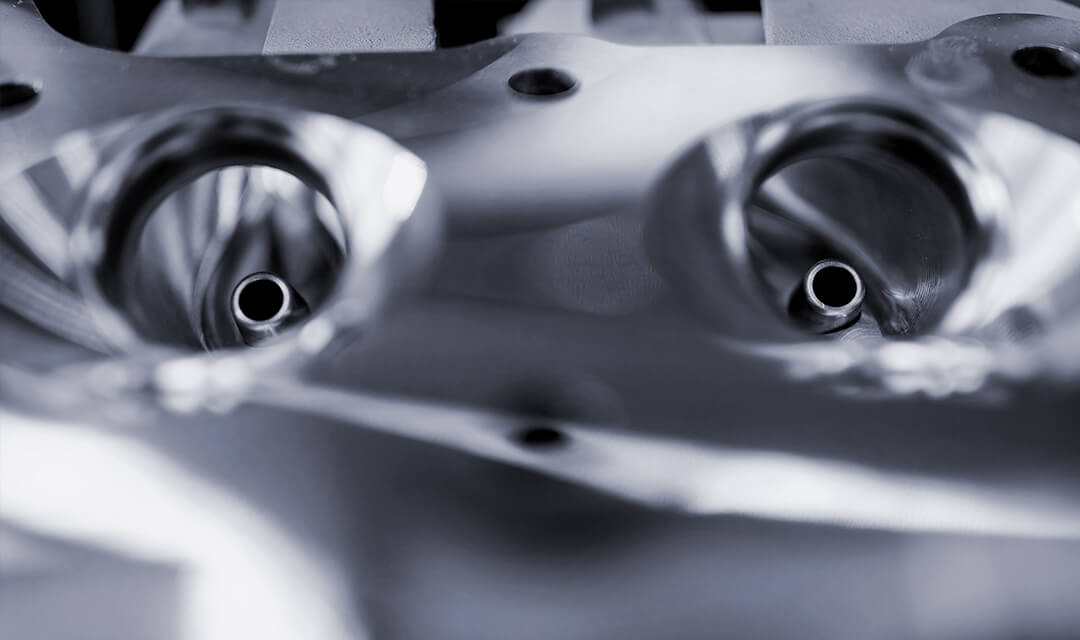

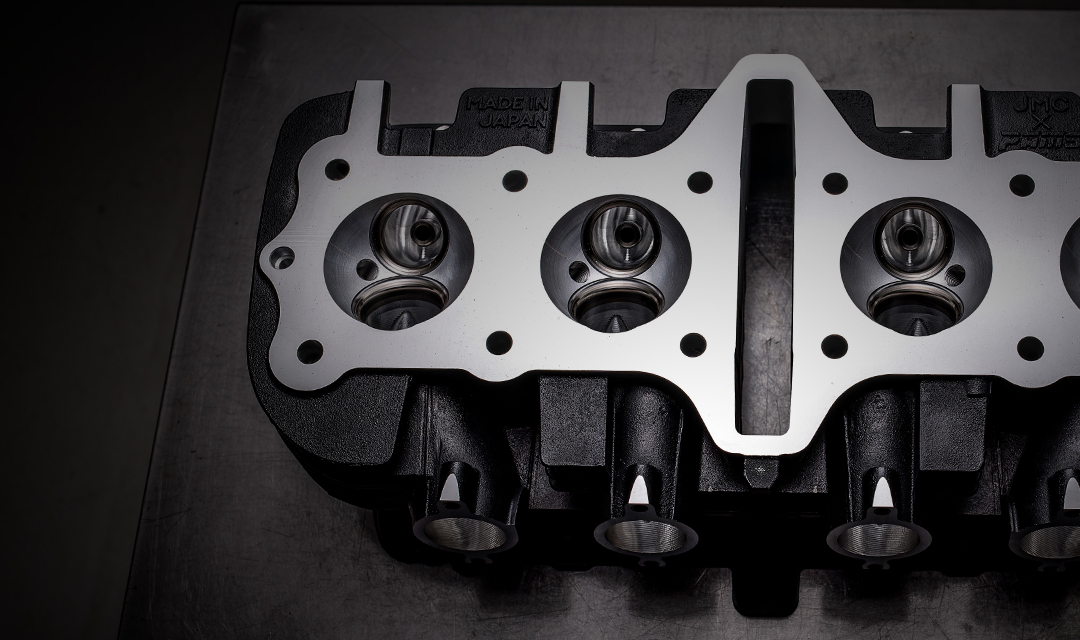

We created several prototypes with varying port cross-sectional areas and shapes. Through repeated flow bench tests, we identified the final specifications that resulted in a flow value that surpasses that of a standard head. Additionally, we incorporated the best design that addresses the imbalance between ports 1/4 and 2/3 caused by differences in port shapes.

By considering the larger port size from the design stage, we have achieved a significant port diameter while providing a margin that is only possible with the newly designed casting. This new design has no cracks or penetration problems common with the standard base port processing or poor insulator adhesion due to the thinning of the port wall when the diameter is expanded.

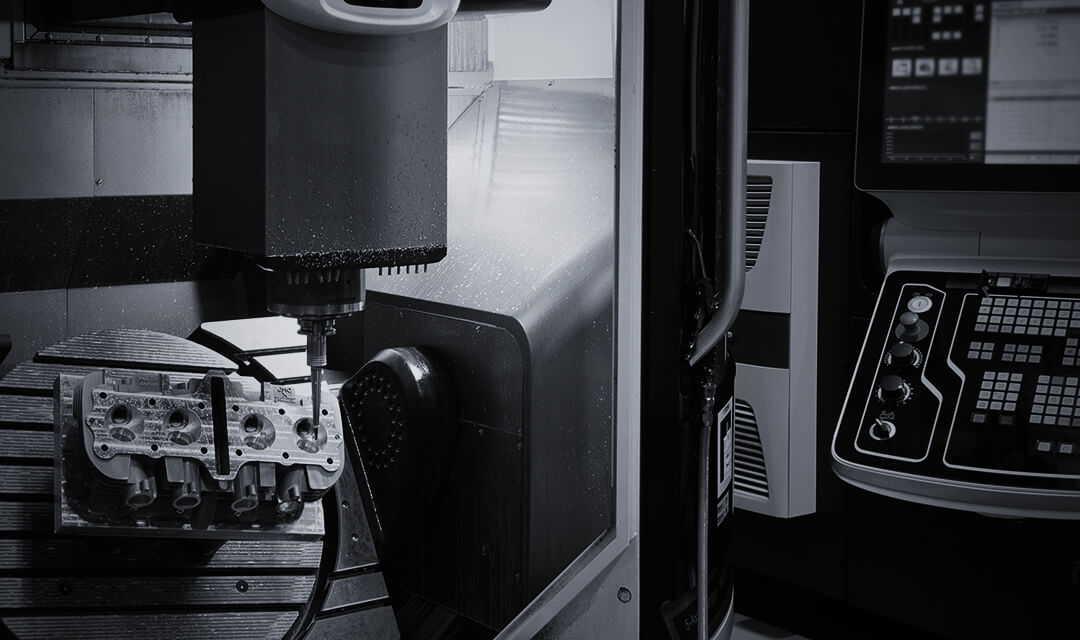

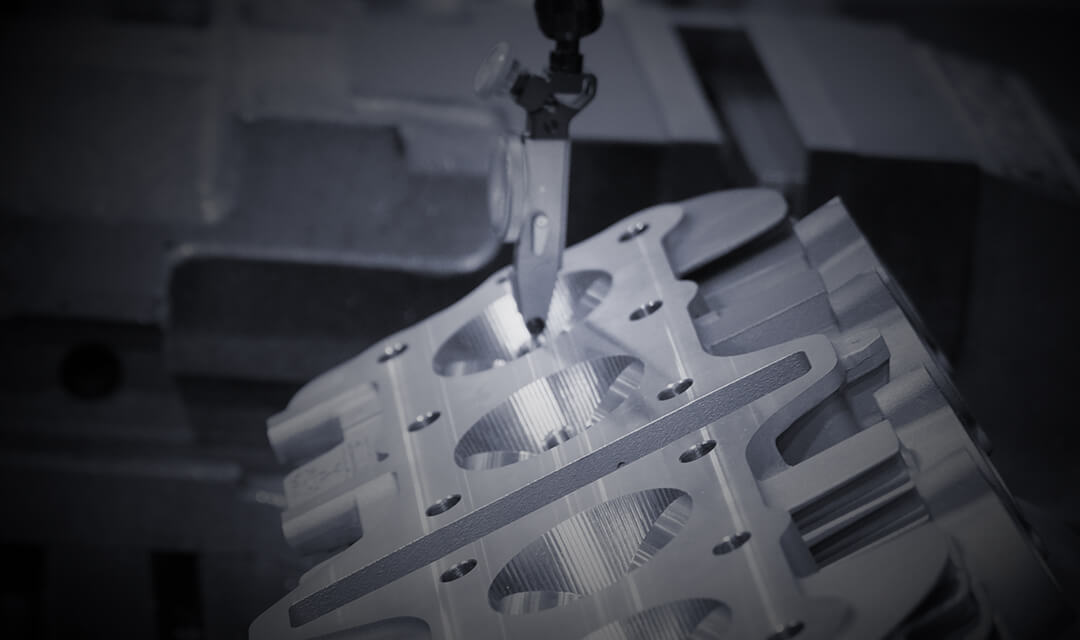

The design finalized due to the flow bench test is converted into CAD data. All intake/exhaust ports are fully machined using the latest 5-axis machining to make the port shapes and volumes uniform and improve intake and exhaust efficiency.

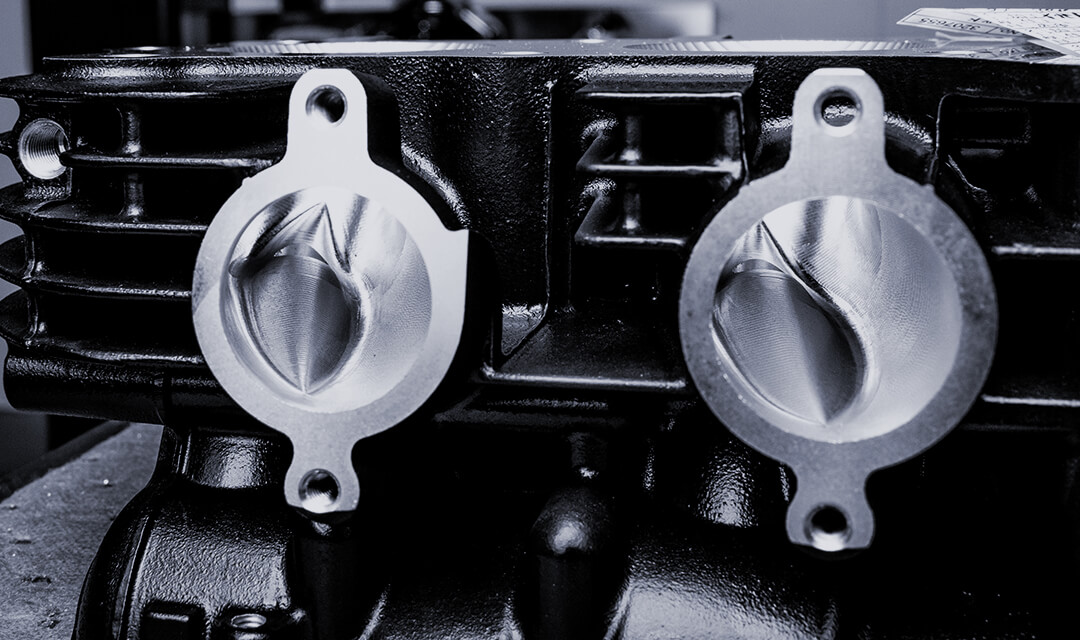

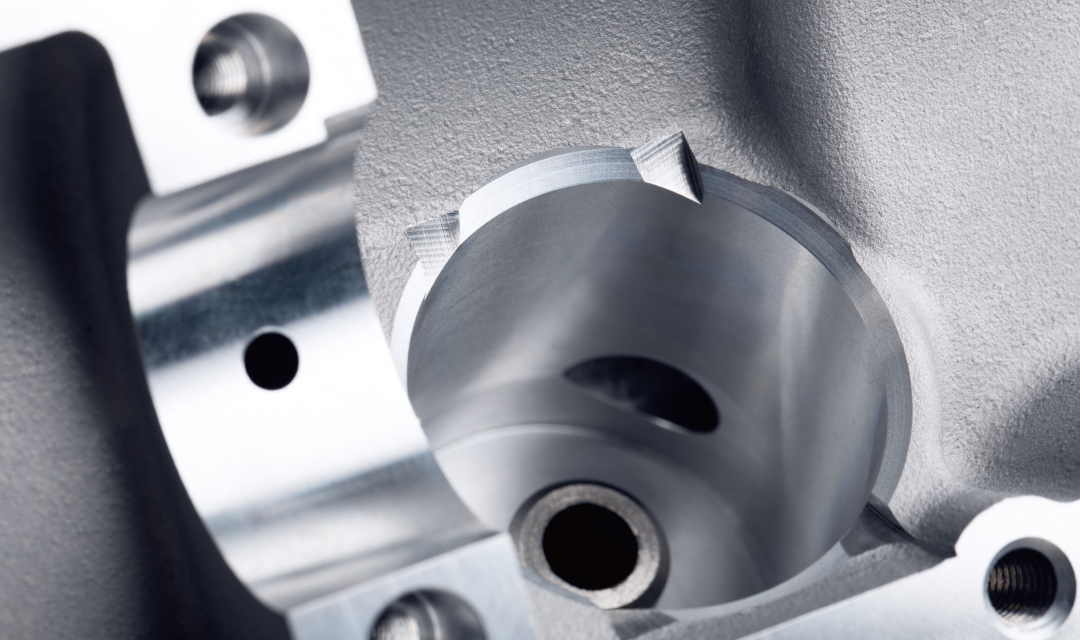

Special tools are used in high-precision machining to create smooth surfaces in the combustion chamber. Accurate sheet-cutting techniques ensure equal volume in each cylinder, producing a synergistic effect.

A highly durable seat ring made of TPR special heat-resistant steel is designed to match the intake 37φ and exhaust 31φ big valve standards. It is also possible to create larger valves through additional machining.

A cast iron SA valve guide with high wear resistance has been used, which has undergone cylindrical polishing for precise dimensional control and improved machined surface roughness. This ensures a better fit and prevents oil leakage into the port without damaging the guide hole when press-fitting the guide into the head.

By adopting a coaxial seat-cutting method that simultaneously cuts the inner diameter of the valve guide and the seat, it has become possible to significantly improve the adhesion between the valve and seat and to align the valve set length precisely.

Thread strength is greatly improved by using a rolling tap to cut the female thread of the cam holder bolt. In addition, it is designed to allow extended-reach bolts that are 5mm longer than the stock version, significantly improving durability when using high-lift cams.

When using a high-lift cam, pre-processing the cam nose relief allows for a cam lift of up to 10.8mm without requiring additional machining to the head

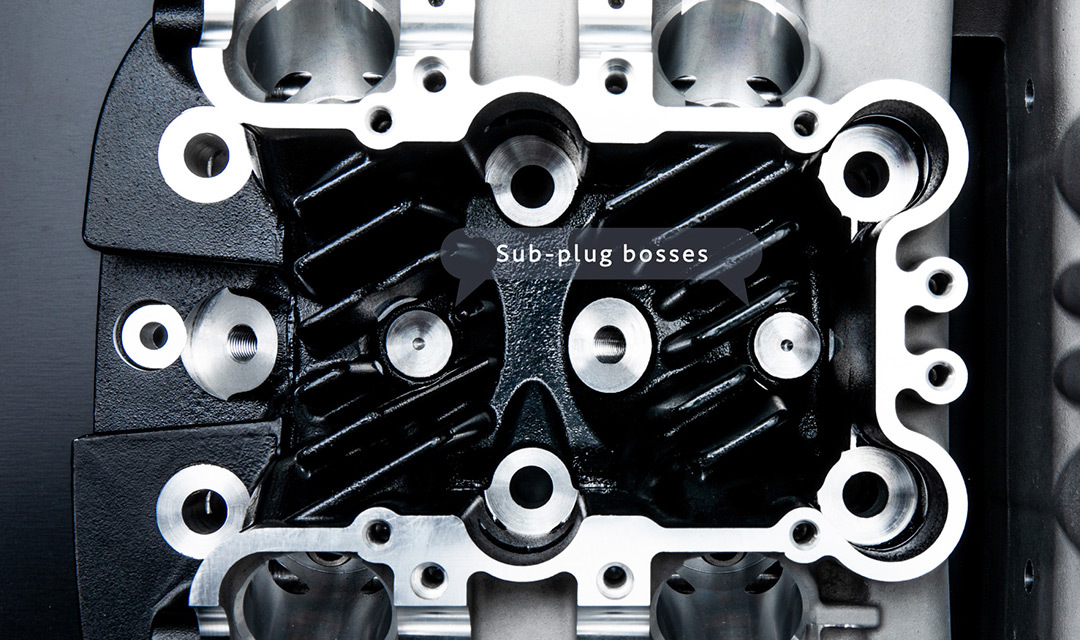

By reducing the diameter of the spark plug from type B to type C, we have secured a margin from the plug hole to the seat ring, reducing the risk of cracks caused by heat and aging deterioration.

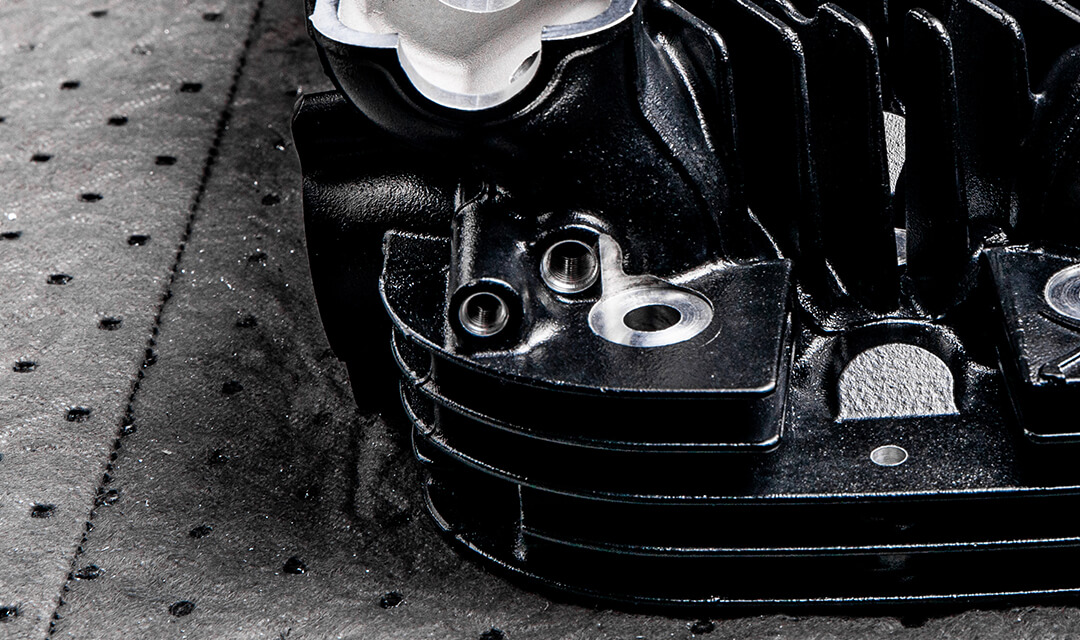

In consideration of cleaning the oil line, etc., each part of the line end is fixed with PT screws.

We considered twin plugs from the design stage and designed the cooling fin shape with sub-plug bosses in advance. The design allows for reliable and easy conversion to twin plugs.

A boss mounting option has been added (requires processing) for the head temperature sensor. This is necessary for advanced settings, such as ignition timing control and injection, using an ECU.