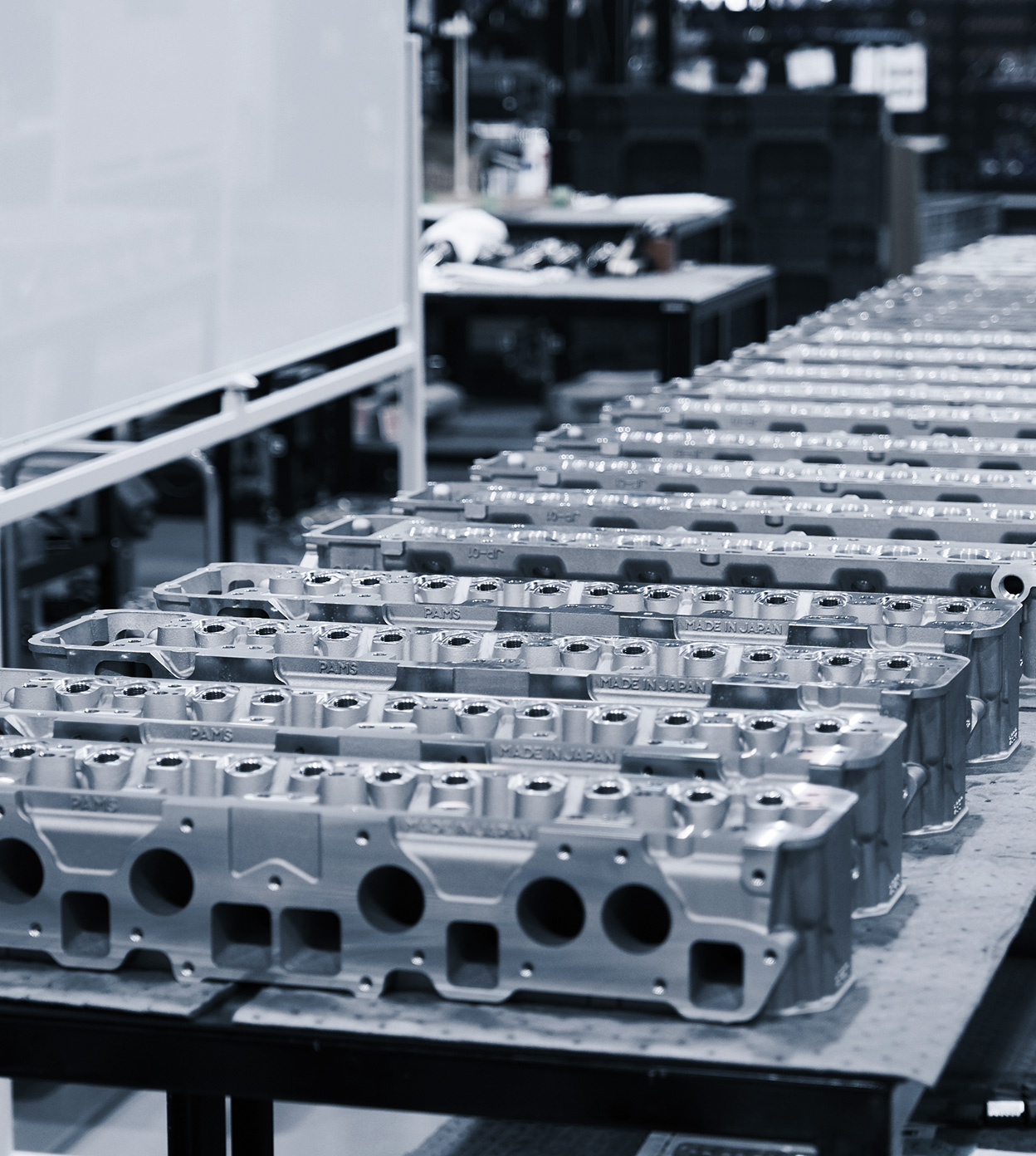

L6 HEAD ver.JP

Pursuit of ideal L6 cylinder head

Lineup

-

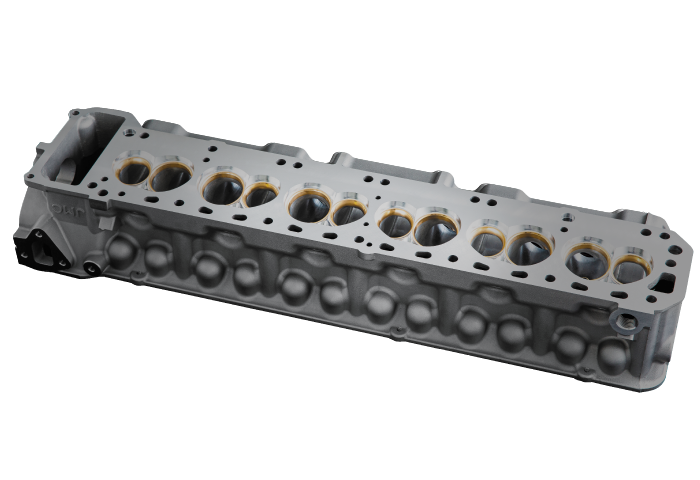

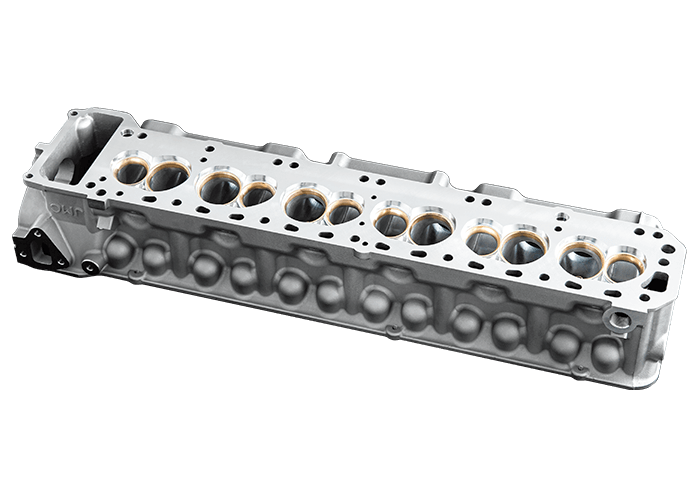

L6 HEAD ver.JP Type.A

Material : AC4CH-T6

All combustion chamber processing work has been completed by 5 axis CNC machining, and this is the most suitable type for making a head that implements each tunerʼ s know-how, such as selecting a valve guide / seat ring according to the purpose, changing the port shape, or polishing the port wall. The valve guide holes, seat ring grooves, and all other parts are already machined, but valve guides and seat rings are not included.

-

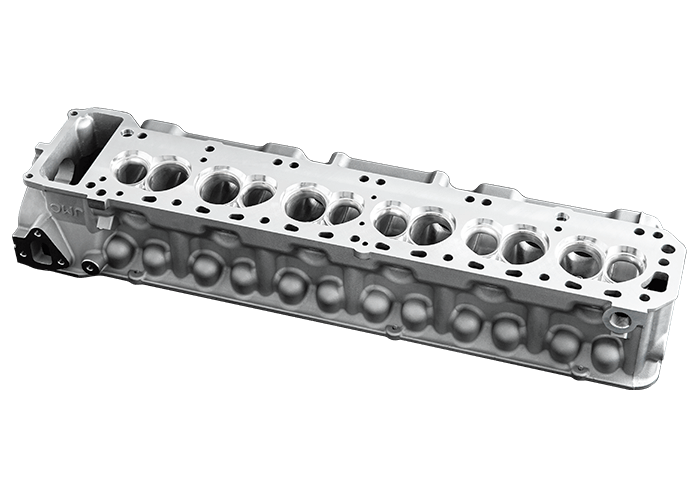

L6 HEAD ver.JP Type.B

Material : AC4CH-T6

In addition to Type A, all combustion chamber processing work has been completed by 5 axis CNC machining. In addition, valve guide press-fitting, fitting of IN / EX seat rings, and seat cutting after press-fitting have been performed. Special heat-resistant steel is used for the seat ring, and the specifications emphasize durability.

-

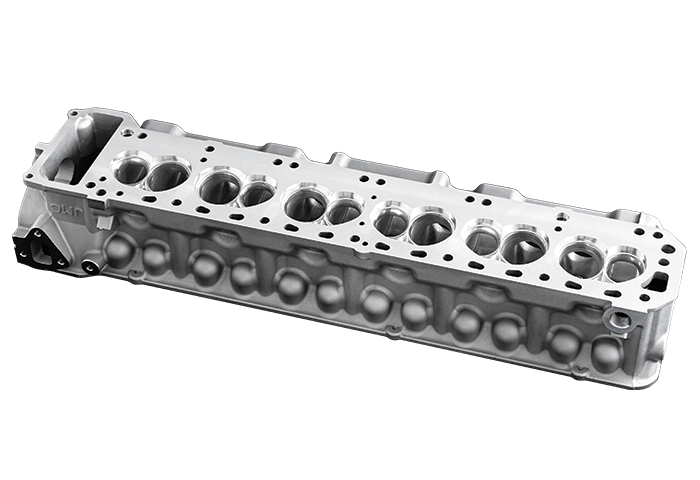

L6 HEAD ver.JP Type.C

Material : AC4CH-T6

In addition to Type A, all combustion chamber processing work has been completed by 5 axis CNC machining. In addition, valve guide press-fitting, fitting of IN / EX seat rings, and seat cutting after press-fitting have been performed. Beryllium copper alloy is used for the seat rings, and the specifications ensure higher performance while considering durability.

-

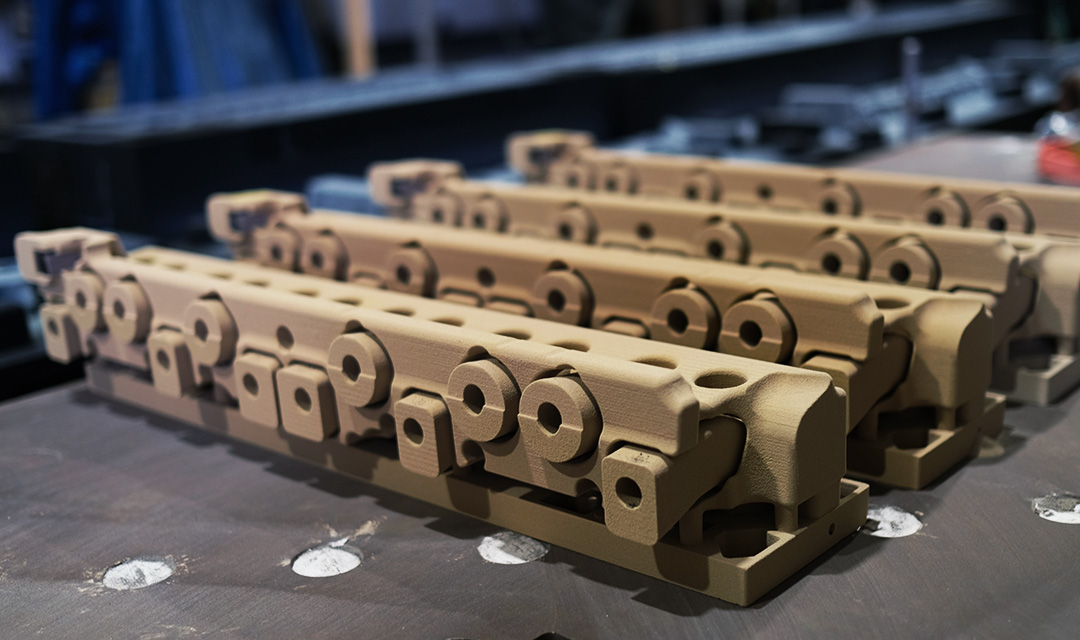

Camholder

Material : AC4CH-T6

This is a high-precision cam holder that has improved accuracy in all aspects including casting, machining, and inspection standards compared to the original products at the time.

The newly designed relief machining for the interference part of the valve spring embodies the feedback from tuned engine builders.

The beautiful appearance achieved through high-precision coaxial machining using the latest CNC for each set can be said to be functional beauty resulting from high machining accuracy and casting quality.

Can be used with all PZ L6 HEAD series, but can also be used with genuine heads such as N42.

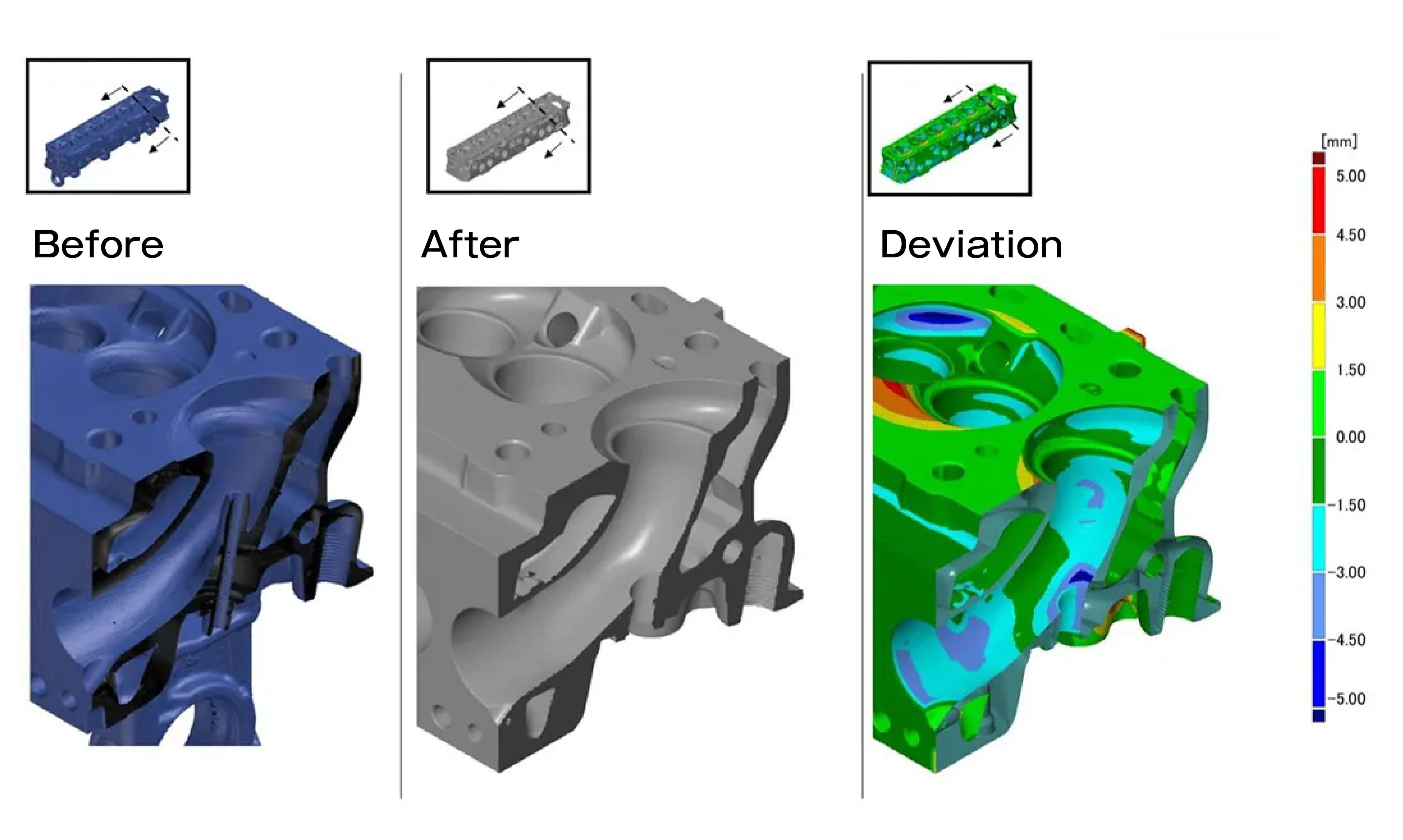

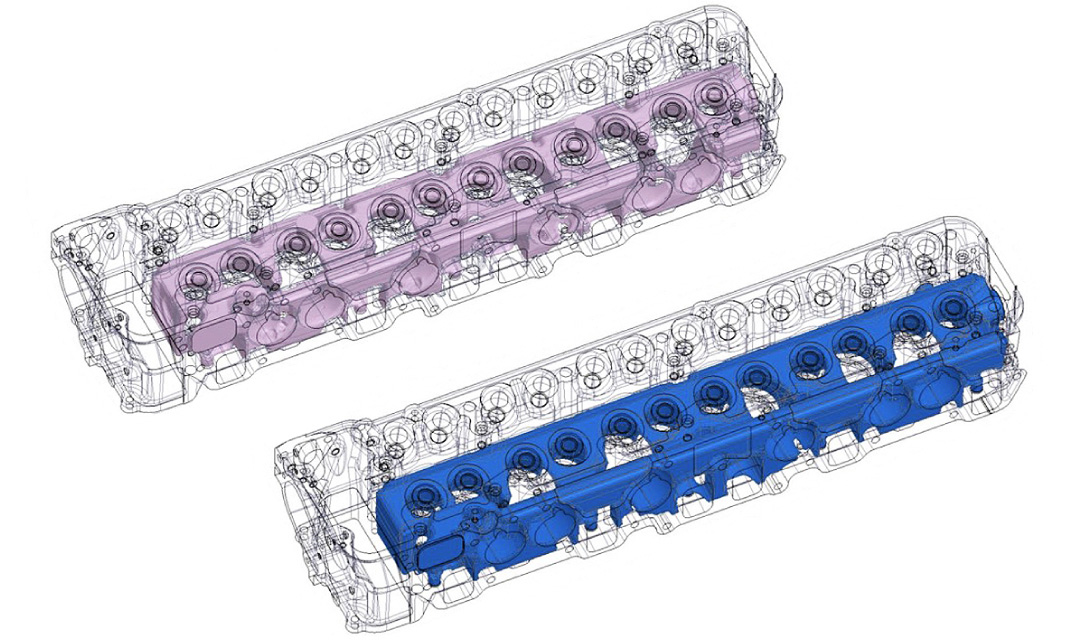

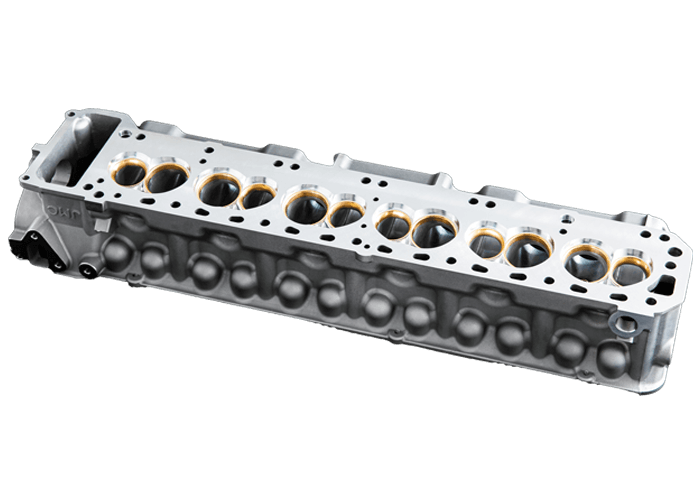

Optimized port and combustion chamber design for incomparable performance achieved

L6 HEAD is based on the genuine L28 head, and by considering problems such as penetrating the water jacket when expanding the port from the design stage, it has a sufficient wall thickness margin even for a maximum port inner diameter of 41mm. It is guaranteed and can be used with confidence for further customization.

HEAD Detail

-

Material

After analyzing the material of the normal head, we adopted AC4CH for higher strength and durability, and then applied T6 heat treatment.

-

Port Design

The ideal port diameters and shapes are newly designed by making full use of a flow tester. Compared to the stock ports, the intake and exhaust efficiency is overwhelmingly higher. Also, even with the greatly enlarged port bore diameter, there is no need to worry about the water jacket penetration problems due to sufficient wall thickness margin.

-

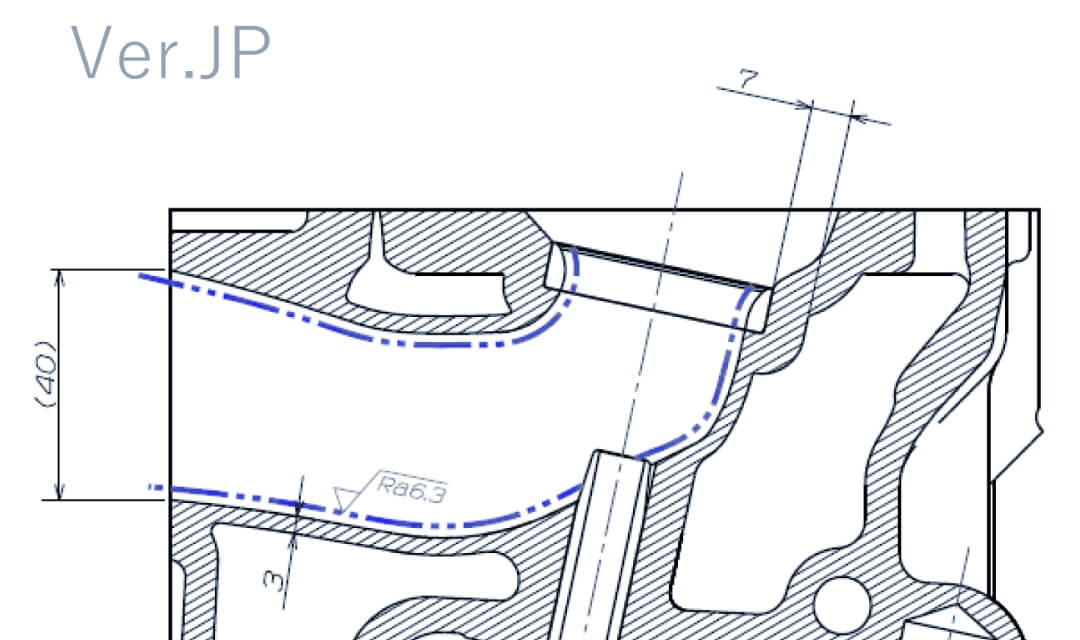

Port margin

While forming a large diameter port compared to normal, the margin thickness to the water jacket is IN 3.5mm / EX 3mm to improve reliability against trouble.

* Margin thickness differs only in the following areas:Under IN spring seat / approx. 2.5mm Head bolt part / approx. 1.7mm

-

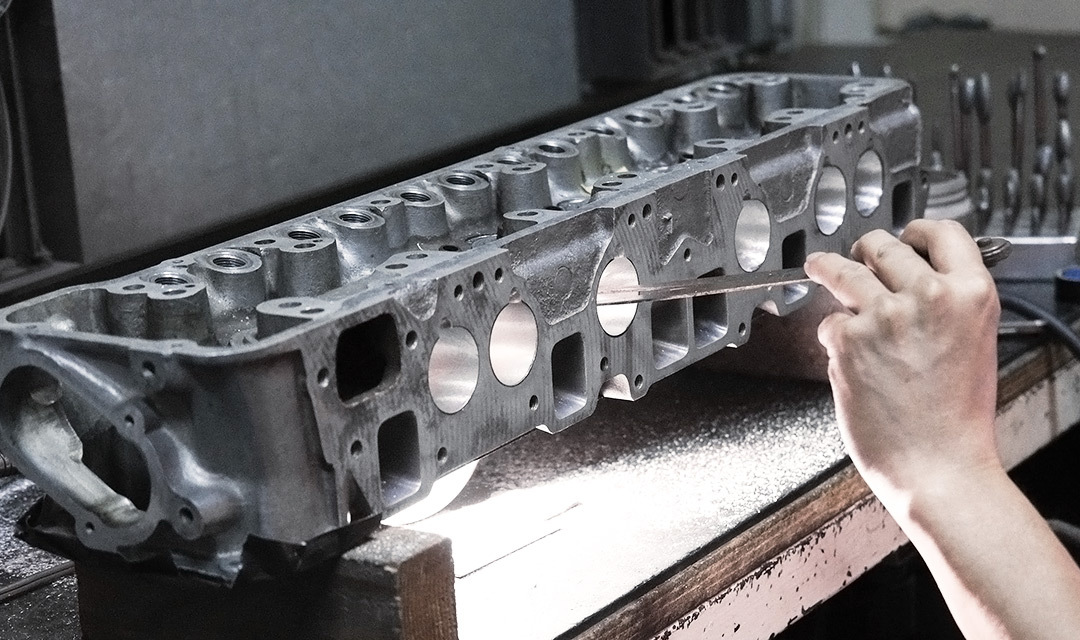

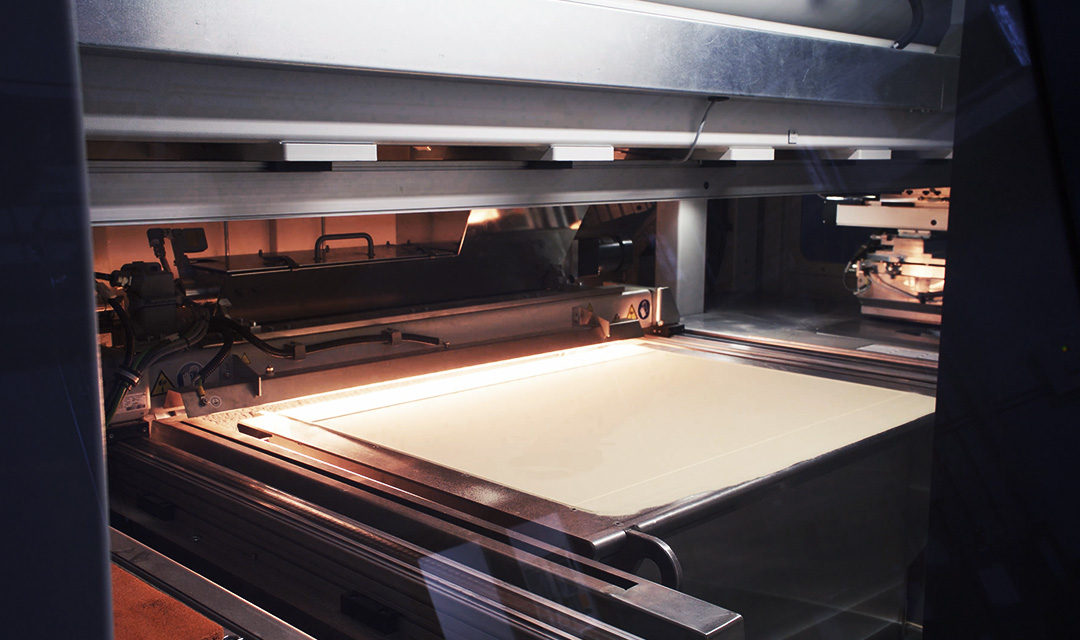

Sand 3D printed mold

The port core used to form the port during sand casting has been created by 3D printer to achieve a precise and consistent casting surface and high dimensional accuracy.

-

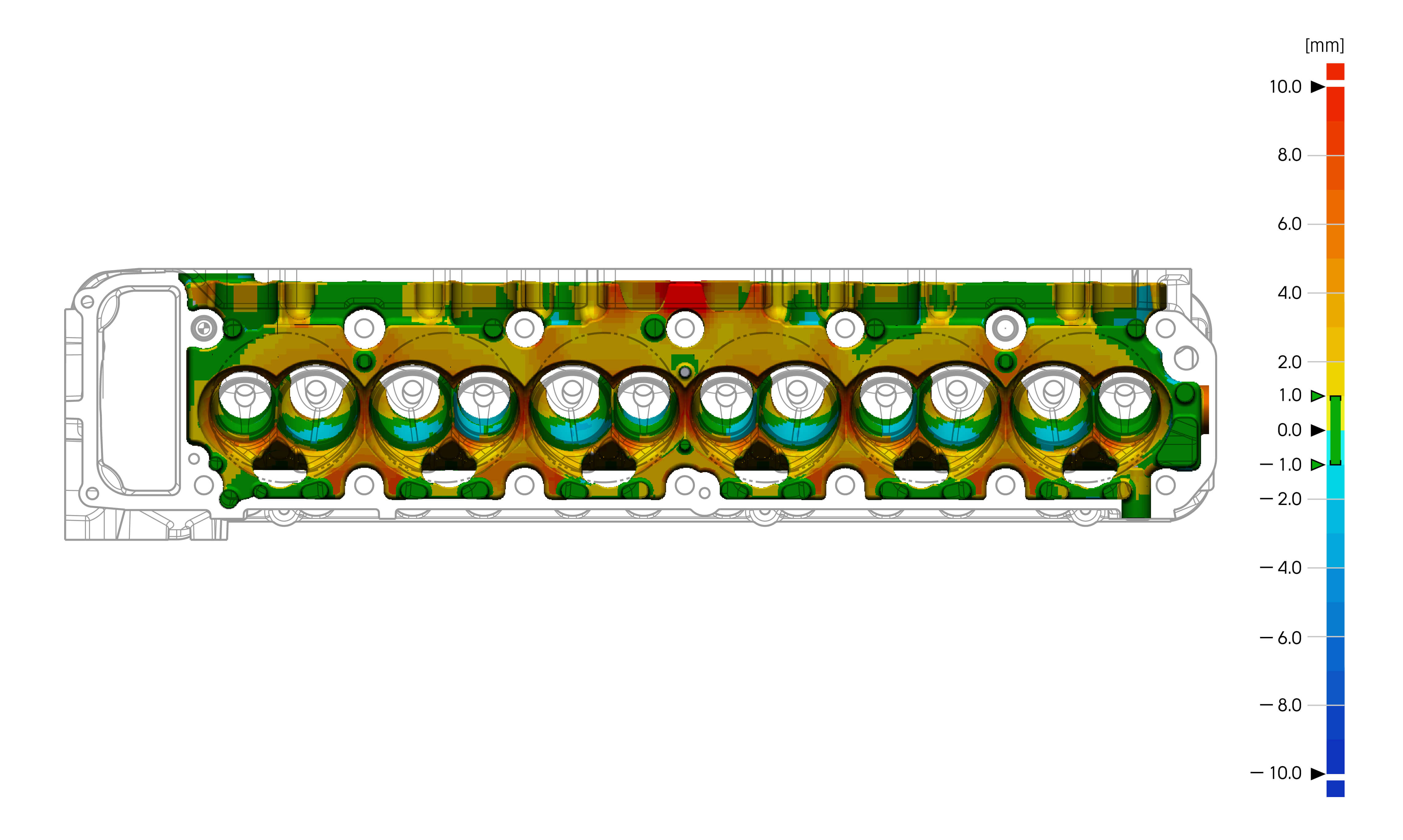

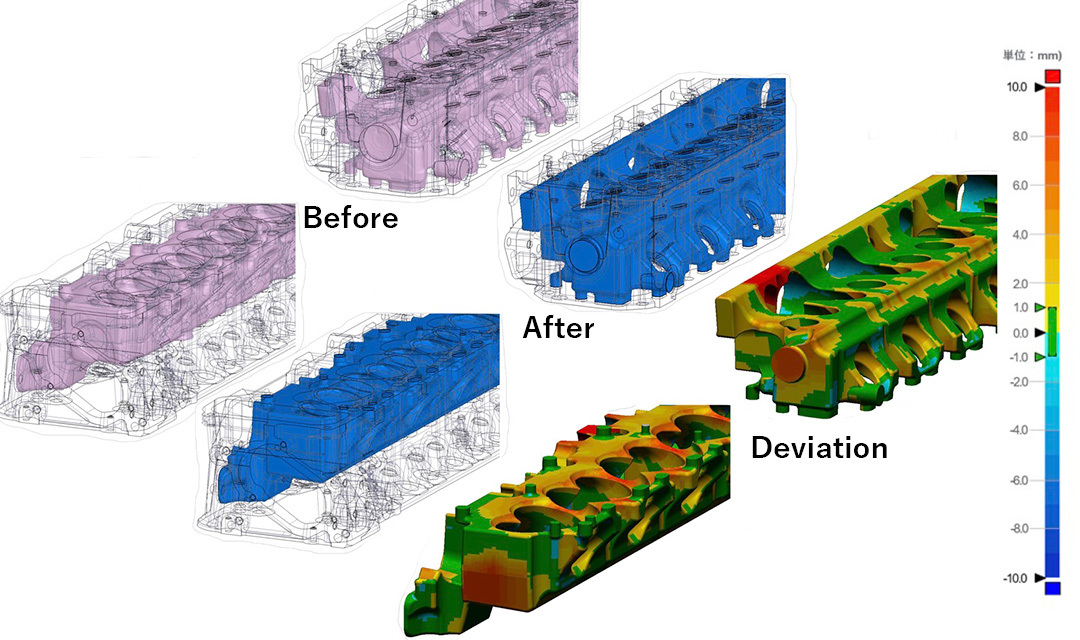

Water Jacket design

The latest analysis has discovered the ideal water jacket design by using cores formed by a sand mold 3D printer. The use of cores molded by a 3D printer eliminates the occurrence of water channel formation defects caused by mold misalignment and other problems. This enables efficient and uniform cooling between each cylinder.

-

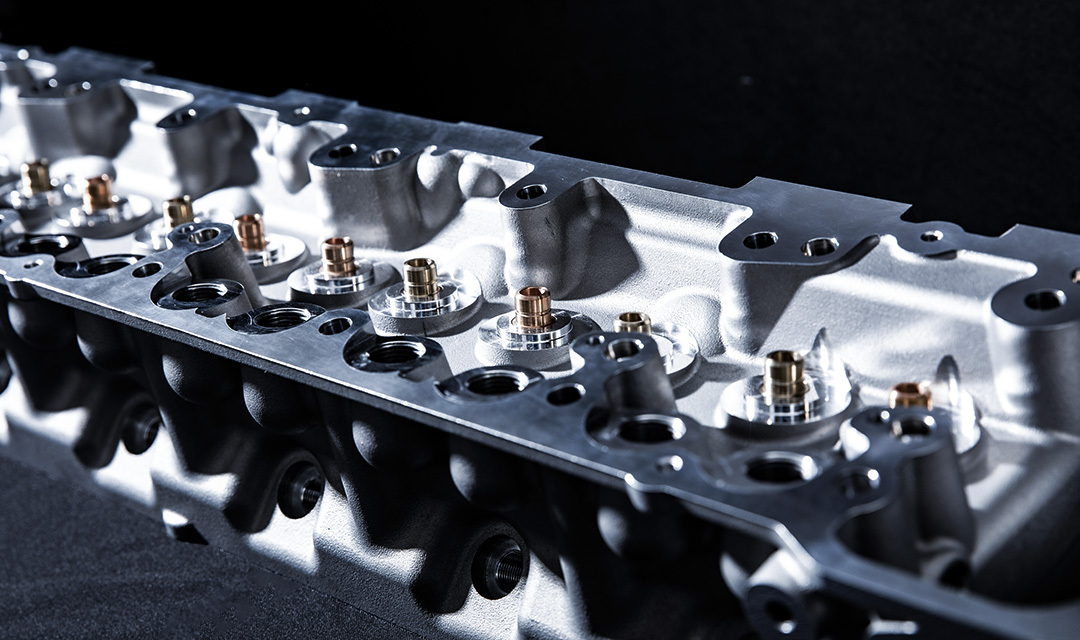

Valve seat cut

By adopting a coaxial sheet cutting method that cuts the inner diameter of the valve guide and the seat at the same time, it is possible to align the valve set length with high precision while greatly improving the adhesion between the valve and the seat. At the same time, it is possible to equalize the volume of the combustion chamber realization.

-

Combustion chamber design

The ideal shape and volume are created from the initial design stage without the need for argon welding, etc., which is required to achieve a high compression ratio. Therefore, the head body does not suffer from strength degradation due to excessive surface grinding or thermal distortion.

-

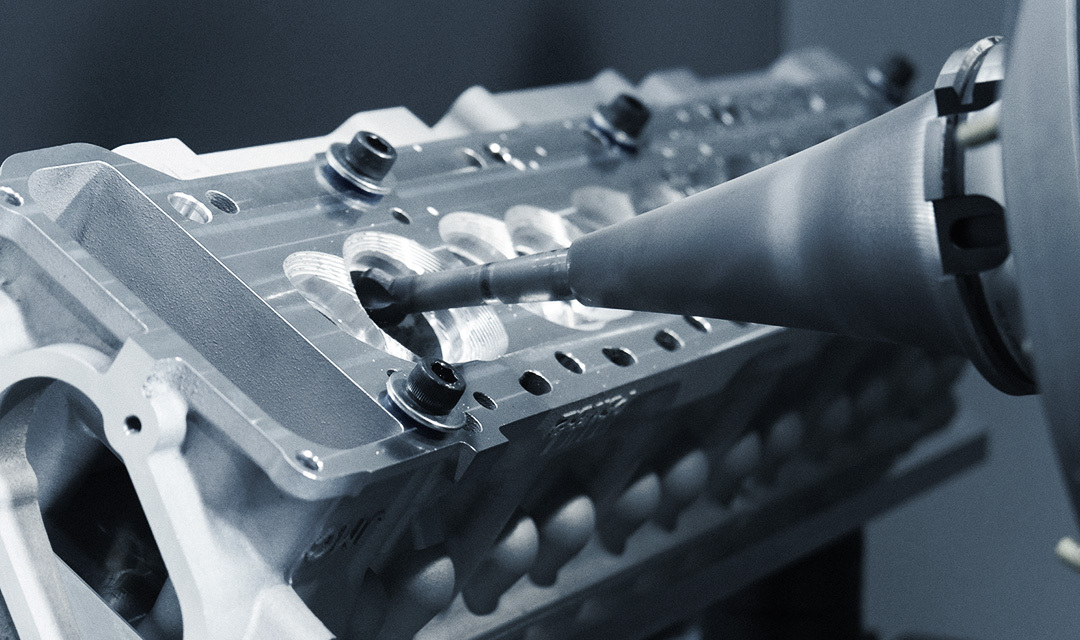

Combustion chamber finishing

The latest 5-axis CNC machining process has insured combustion chamber molding with no volume error between each cylinder.

-

Valve seat ring

By securing the wall thickness margin from the seat ring press-fit groove to the water jacket, support rigidity is improved and the risk of ring dropout, etc., is greatly reduced.

PZ / Products Spec

L6 HEAD Ver.JP

-

HEAD BODY

NEW CASTING

-

MATERIAL

AC4CH

-

CASTING METHOD

SAND MOLD LOW PRESSURE CASTING

-

HEAT TREATMENT

T6

-

PORT SIZE

IN:φ41 → φ43.5 SEAT RING INNER DIAMETER / EX VERTICAL 40mm, IN HORIZONTAL 31.5mm

-

PORT WALL MARGIN:THICKNESS

IN:3.5mm / EX:3mm (AGAINST WATER JACKET)

* IN VALVE SPRING UNDER THE SEAT SURFACE 2.5mm]

* HEAD BOLT PART 1.7mm] -

HEAD BOTTOM SURFACE MARGIN THICKNESS

11 mm (AGAINST WATER JACKET) * EX PORT EXCEPT THE SMALL SEGMENT OF THE LOWER PART 6.8mm

-

REFERENCE HEAD HEIGHT

108mm

-

COMBUSTION CHAMBER

5-AXIS CNC PROCESSING( HEART-SHAPED MOLDING)

-

STANDARD COMBUSTION CHAMBER VOLUME

39cc (± 0.5)

-

WATER JACKET

NEW WATER JACKET DESIGN BASED ON FULL CT SCANNING INTERNAL ANALYSIS TO OPTIMIZE THE COOLING EFFICIENCY

-

VALVE SEAT RING MATERIAL

Type B

SPECIAL HEAT RESISTANT STEELType C

BERYLLIUM COPPER -

SEATRING HOLE DIAMETER/DEPTH

HOLE DIAMETER IN:47.5mm(-0.05~0.07)EX:39.2mm(-0.05~0.07))/ DEPTH:7.2mm(± 0.05)

-

VALVE GUIDE MATERIAL

Type B/C

IN / ALUMINUM BRONZE EX / PHOSPHOR BRONZE -

VALVE GUIDE HOLE DIAMETER

IN/EX 12mm(+0.01)

-

ADAPTIVE VALVE DIAMETER

IN:46mm EX:38mm

* Margin dimensions may vary slightly depending on castings.