Directed by

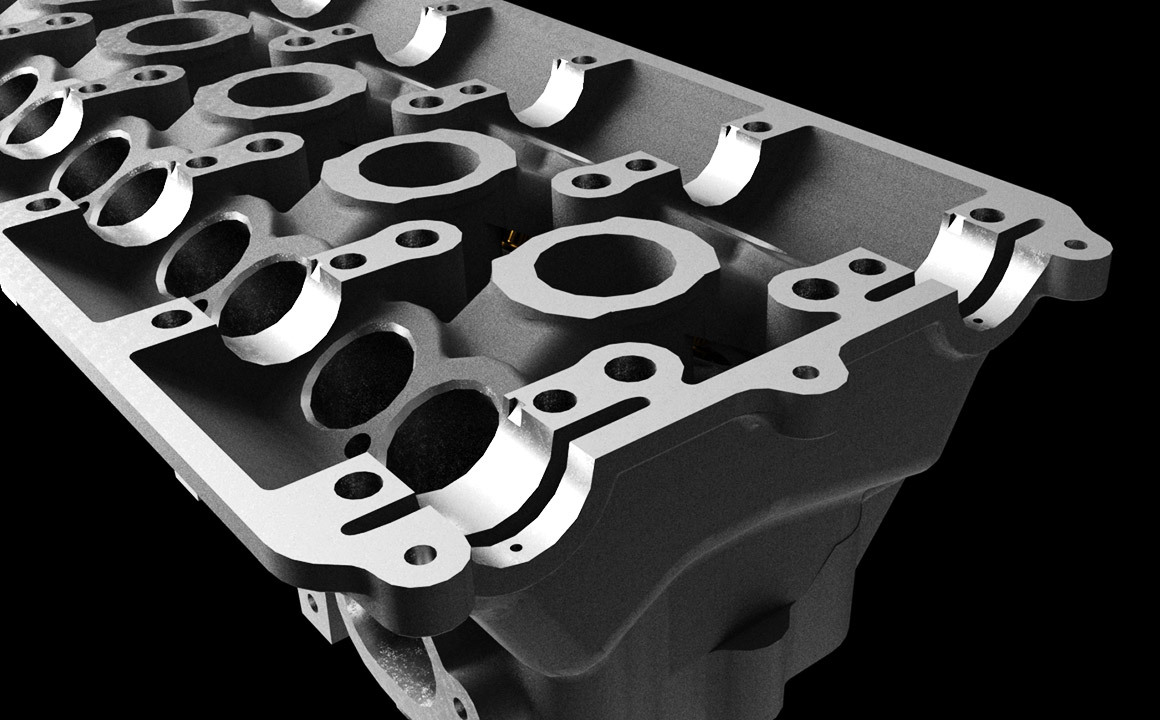

PZ S20 HEAD

-

S20 Standard Model

Reproduction of normal head with overwhelming quality accuracy using 3D printed 1-piece cores.

1,300,000 JPY plus tax

-

S20 Tuned Model

Combustion chamber shape and IN/EX port shape changed, and fully machined by 5-axis CNC.

1,500,000 JPY plus tax

The S20 is a straight-6 DOHC engine that inherits the DNA of racing engines.

It was installed in famous cars such as the Hakosuka GT-R ( PGC10,KPGC10 ) , the Kenmeri GT-R ( KPGC110 ) , and the Z432, and is a race-bred engine that naturally combines a sound and feeling that you can never get from a general-purpose engine.

-

Feature 01

Advanced Casting Materials

After material analysis of the standard head, AC4CH was adopted for higher strength and durability, and T6 heat treatment was applied.

Cooling performance is improved by using aluminum material that boasts approximately 1.5 times higher thermal conductivity than the standard head. -

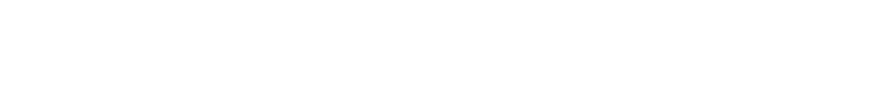

Feature 02

Highest casting quality

High-grade casting materials are used, with the occurrence of casting cavities minimized by low-pressure casting under the latest control. Before machining, all products are subjected to internal inspection using CT scans to guarantee quality.

-

Feature 03

Port design

【S20 Standard Model】

A 3D printer is used for the cores used to form ports during casting to achieve a well-rounded casting surface and high dimensional accuracy.

【S20 Tuned Model】

The IN/EX ports are seamless and stepless, and are finished by state-of-the-art 5-axis CNC to reduce cylinder-to-cylinder differences and improve intake and exhaust efficiency.

-

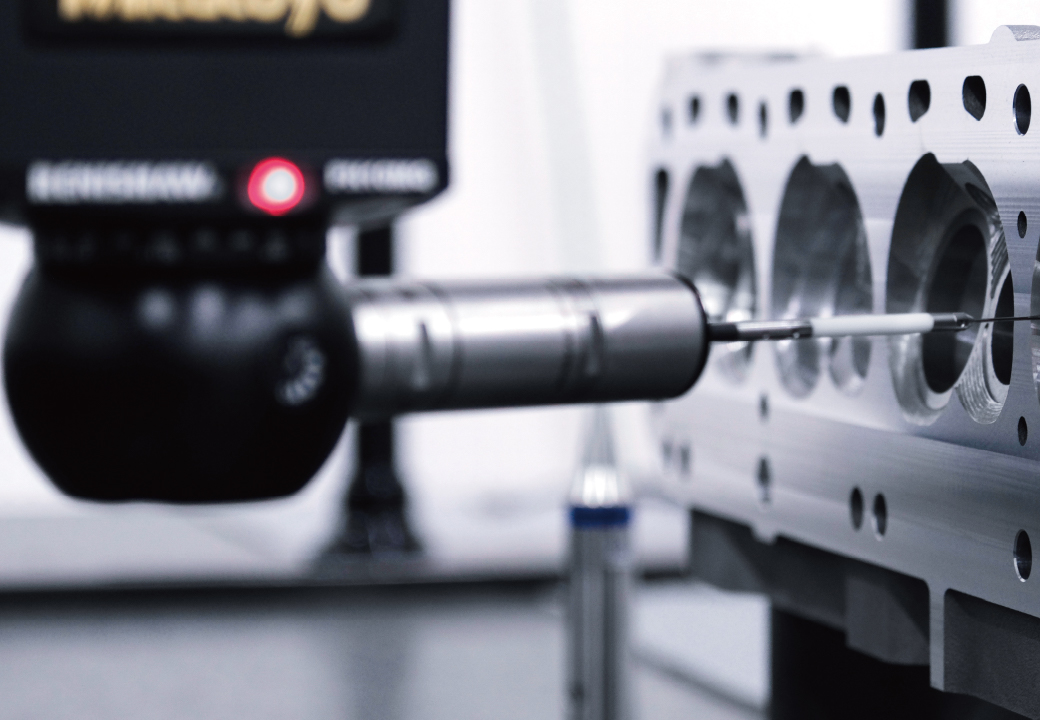

Feature 04

Water jacket design

The flow of cooling water was improved after analyzing the water jacket of the original head using the latest CT scan. Furthermore, the casting technology, which is far superior to that of the genuine head at that time, has been used to suppress the cooling imbalance between cylinders caused by individual differences in the cooling water channels and improve cooling efficiency.

-

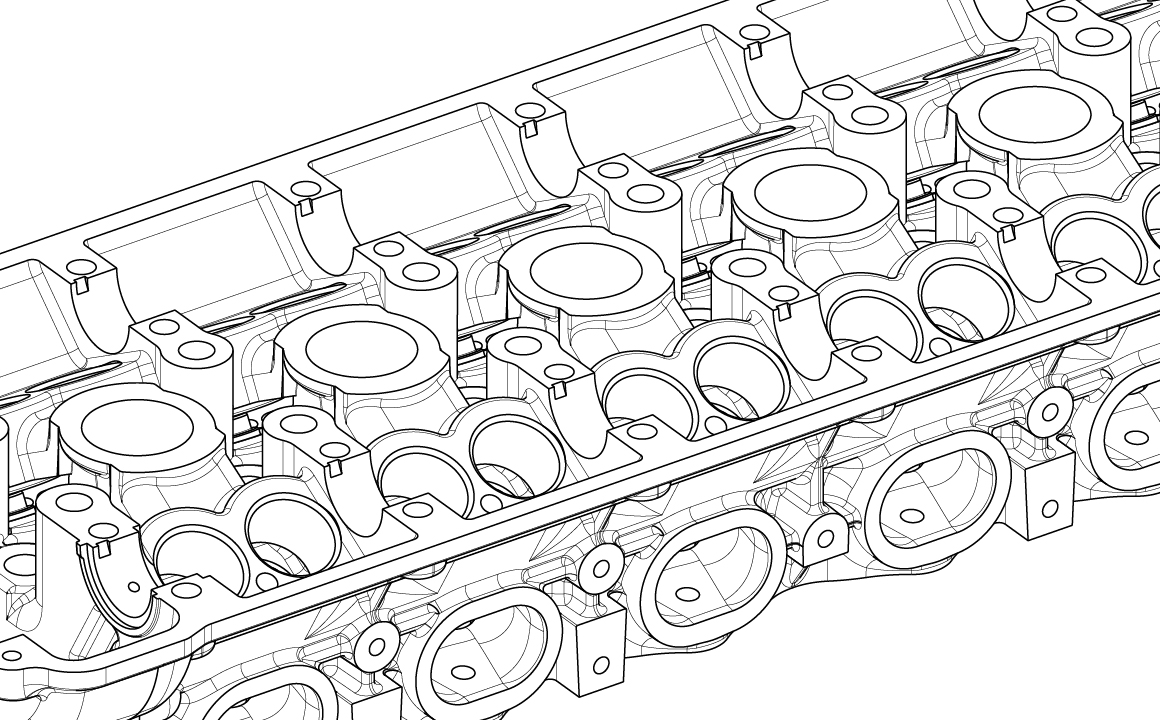

Feature 05

Precision machining of combustion chambers

The combustion chamber is formed by the latest 5-axis CNC machining, and the shape and volume of the combustion chamber are precisely aligned between cylinders.

【Tuned Model:38cc 】

【Standard Model:42㏄】 -

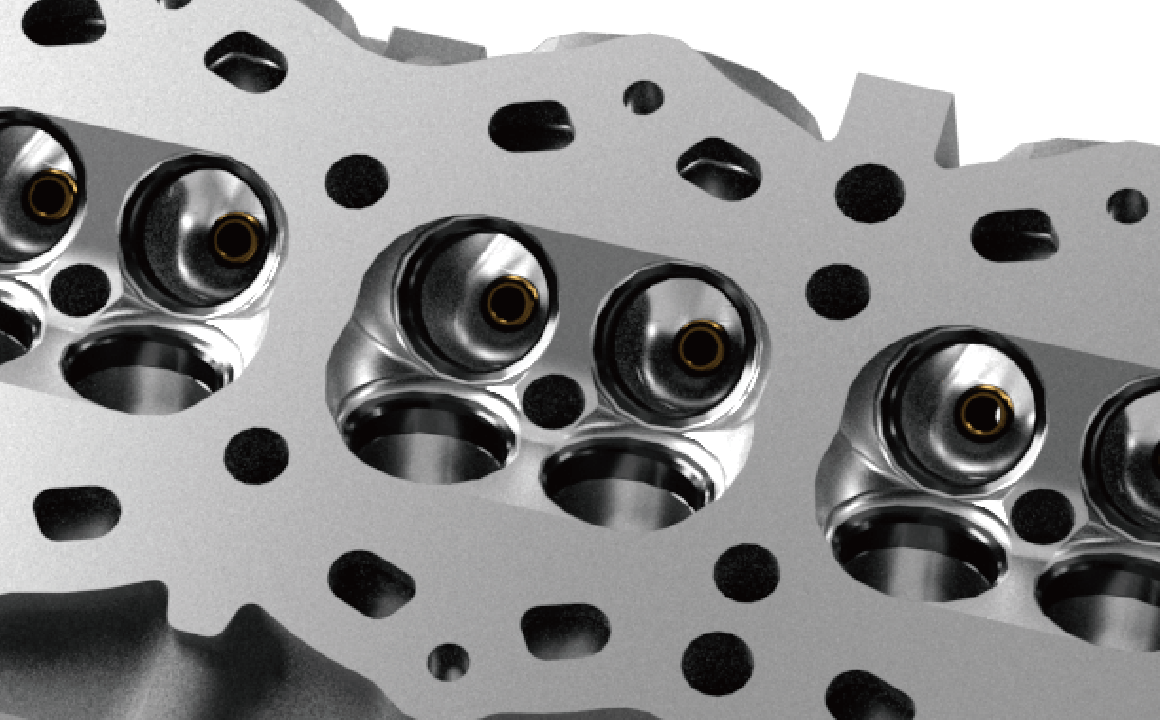

Feature 06

Valve seat cut

By adopting the coaxial seat cutting method, which simultaneously performs valve guide bore cutting and seat cutting, the valve set length can be precisely aligned and the combustion chamber volume can be made uniform at the same time.

-

Feature 07

Head cover mounting boss added

The head cover mounting boss has been increased from one to three locations (rear side) to reduce the load on the mounting area, and the reinforced design suppresses cracking that can occur on the head cover, which also suppresses oil leak trouble.

PZ S20 HEAD Spec

PZ S20 HEAD

-

HEAD BODY

NEW CASTING

Seat ring press-fit / Valve guide press-fit / Seat cut -

MATERIAL

AC4CH

-

CASTING METHOD

SAND MOLD LOW PRESSURE CASTING

-

HEAT TREATMENT

T6

-

PORT WALL MARGIN:THICKNESS

4mm(against water jacket)

-

REFERENCE HEAD HEIGHT

119mm(± 0.5)

-

COMBUSTION CHAMBER

5-AXIS CNC PROCESSING

-

STANDARD COMBUSTION CHAMBER VOLUME

Standard Model

42 cc(±0.5)

Tuned Model

38 cc(±0.5)

-

WATER JACKET

NEW WATER JACKET DESIGN BASED ON FULL CT SCANNING INTERNAL ANALYSIS TO OPTIMIZE THE COOLING EFFICIENCY

-

VALVE SEAT RING MATERIAL

SPECIAL HEAT RESISTANT STEEL

-

VALVE GUIDE MATERIAL

IN / ALUMINUM BRONZE EX / PHOSPHOR BRONZE

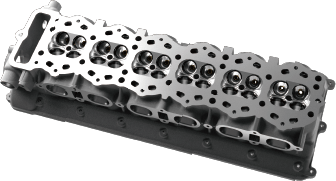

S20 HEAD COVER | Mg

-

Unpainted

300,000 JPY plus tax

This product is treated by conversion to improve corrosion resistance.

-

Crystal painting Stock color

330,000 JPY plus tax

This version has a wrinkle paint in addition to the chemical conversion treatment.

-

Feature 01

Lightweight materials

AZ91D, a Mg-Al-Zn magnesium alloy with excellent mechanical properties, is used to achieve a weight reduction of approximately 30% compared to normal head covers made of aluminum alloy.

-

Feature 02

Reinforcement Design

As with the head, mounting bosses are added in three locations to suppress oil leak trouble and other problems caused by cracks.